.

. .

.- True aluminum ribbon high frequency unit

- Twin Ceramic hemispherical cone mid-woofers,

Capacitorless Electronic damping to control excess bass ringing and rising impedance of the voice coils. Frame damping with Vibra-Putty.

- Main

filter inductor by Jantzen, The Jantzen Cross-Coil inductor is

Immersion LN2 treated at JENA LABS. Flat-foil high-purity copper with

PE separator film. Proprietary

Overwrap with Silent Running Audio - 'SRA blue damping sheet. Air core

technology from the world leader in flat foil inductor technology.

- Hi frequency filter cap by Auri-T. Teflon..likely the best there is, Wrapped with 'SRA blue damping sheet. and then over-wrapped with Iso-felt.

- Bass compensation inductor by Erse. The "Super Q" series offers super low DC resistance, highly controlled 'Q' factor, pure copper wire, and over 500 watts of current capability.

- Choice of Cardas binding posts: Traditional nut on post, OR the "Patented Post", compression bar with single tightening knob [approved in Europe ]

- Tweeter level: Choice of adjustable L-Pad OR 2 position switch [ flat and -3dB]

- All internal wire is multi-stranded JENA LABS Ultra-Wire 18G, full Immersion Cryo Process

- All connection joints soldered with Cardas Quad Eutectic solder

- Tweeter connection with threaded post and nuts, treated with JENA Connect contact fluid

- Stainless steel crossover plate 100% custom made, BeadBlast satin finish. Damped with Silent Running Audio 'SRA blue damping sheet'

Moderate impedance: Nominal higher than 8 ohms in low and midband, nominal 8 ohms over 4kHz

OTL and transformer tube amp friendly.

Equally at home with bipolar and FET based power amps.

Developed with 15 watt and 30 watt PP tube amps, 300W FET amps, 250 watt Bipolar amps, and OTLs in 60 watt an 240 watt capacity.

Contact Jennifer e-mail@jenalabs.com

..

pictured below is the completed speaker design.

..

.

. .

..

All are solid Maple, these were stained red.

All are solid Maple, these were stained red.Early test prototypes:

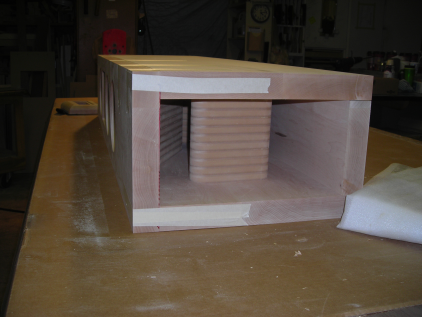

Long ago ideas were prototyped in full scale tests.

Long ago ideas were prototyped in full scale tests..

At left: In Sunburst red (No Flash)

At left: In Sunburst red (No Flash)  Same speaker, with Flash

Same speaker, with FlashLatest pictures of the final stages will be showing up over the next week but here are some pictures of the first enclosure to reach finishing stages.

Natural finish No flash.

Natural finish No flash.  Same with flash. .

Same with flash. ..

Tweeter Panel at left...

Tweeter Panel at left...

And in place at picture above right.

November 1st 2007. We saw the first cutting of the production maple components.

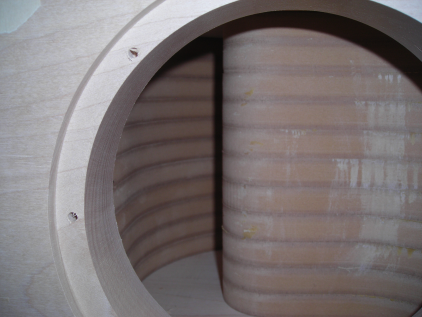

Just look at those stacks of high precision slabs just waiting for their turn in the NC mill. The 1.75 inch slabs are constructed of edge laminated furniture grade clear hard rock maple, fully cured and stabilized, then edge bonded, and final-milled to precise thickness and flatness. In the views above you will see the fabulously accurate NC multi-head mill at work, cutting the first pieces. Jennifer, in the red sweater, protects her hearing as Milling proceeds... you can see her below testing the fit of one of the Thiele and Partner ceramic drivers, albeit one that has not yet undergone the 5 to 6 hour modification process that the finished speaker system will use, and as some of you have heard in the prototype test cabinets.

.

. Ribbon tweeter fit test.

Ribbon tweeter fit test.No garage hack, sloppy table saw-hand router buildup for this production speaker project....We are making full use of this multi-million dollar facility to ensure accuracy, repeatability, finish consistency and ultimate quality control...

.

.Glue-up started November 26 - 07

.

.

. .

..

.

. .

..

.

. .

..

.

. .

..

.

. .

..

.

. .

..

.

.